Facilities

Over 100,000 Square Feet of State-of-the-art Manufacturing Space

Processing

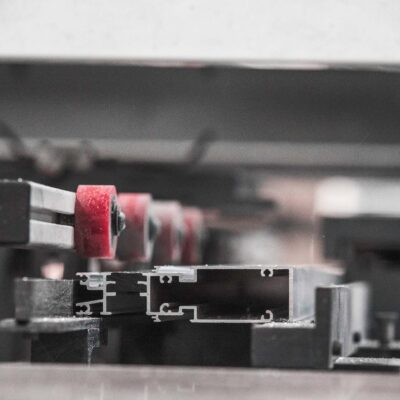

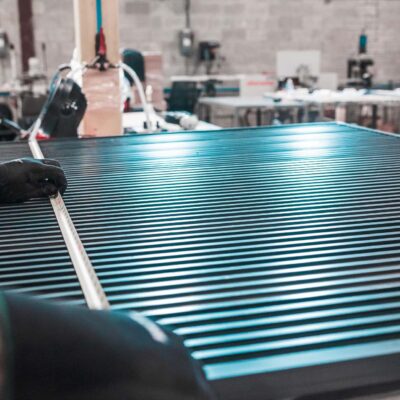

Blackline Aluminum utilizes the latest technology to get information from the drawings to the final product. Our production line uses state-of-the-art automated machining, processing centers, and error-free ERP systems. Barcode scanning allows us to control and analyze every step of production from zero to completion. We use real-time inventory visibility and all high-tech machinery to ensure our customer’s satisfaction with our product and time management.

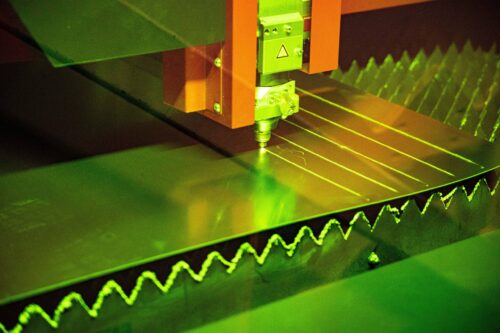

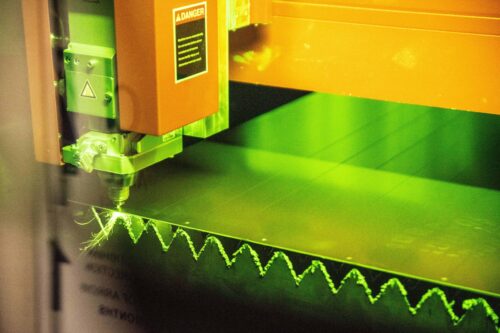

Panel

Our fully equipped panel line is designed to provide the best possible products. Our in-house design / engineering team works with the latest software to bring any design or product to reality with our precise laser cutter, meticulous vertical CNC router, and remarkable 200-ton CNC bender, working with the highest quality materials and QC process we ensure that our products meet the test of time.

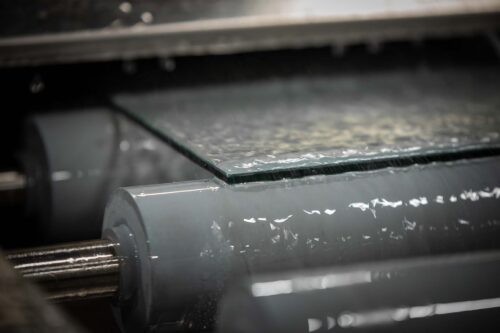

Glass

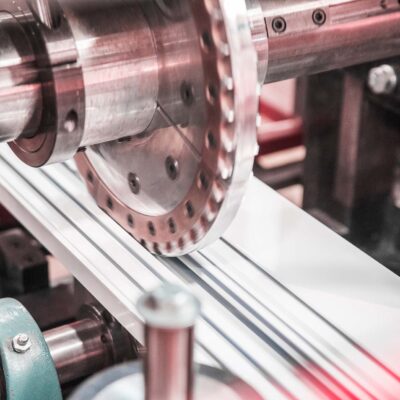

Blackline Aluminum has the most advanced glass equipment, including a computerized storage system. Jumbo Cutting Tables, Tempering Machine, Roll Coating, etc. All give us complete control of every stage of glass production, from glass quality and waste management to the highest production output, enabling us to run the whole operation smoothly and efficiently.

Machinery

Processing – Azon

Panel – Bystronic

Glass – Robotic Loading

Assembly – Automated Silicone Dispensing